PVA Sponge Cube for Developing Biofilm

- On Oct, 29, 2023

- admin

- Others, PVA Sponge

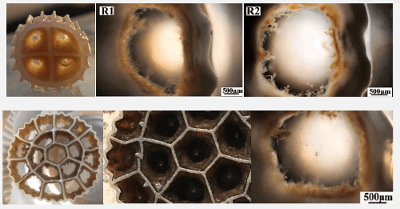

In wastewater treatment process, many use PVA sponge cube for promoting to develop biofilm. The biofilm is a by-product that develops throughout the microbial growth process. Freely dispersed microorganisms in a water solution cannot form a biofilm unless they are residing on a static surface, such as a PVA sponge cube.

The presence of a biofilm serves as an indicator of bacterial growth in the solution. Microorganisms start to proliferate once they settle on a substrate, and this bacterial growth eventually coalesces into a cluster, forming a film. Once the film is established, it acts as a protective barrier for the microorganisms, shielding them from external intrusion.

PVA sponge cube is a good source for the microorganism to reside and eventually form the biofilm.The PVA sponge cube provides an ideal environment for microorganisms to settle and eventually form a biofilm.

Biofilm Development Stage

Microorganism will attach on many surfaces, such as rock, coarse surface, sewage, water pipe or even human teeth. Regardless the substrate, there are a total 5 stages for a microorganism to form a biofilm.

- Initial attachment.

- Irreversible attachment.

- Mutation I.

- Mutation II.

- Dispersion.

The PVA sponge as MBBR substrate

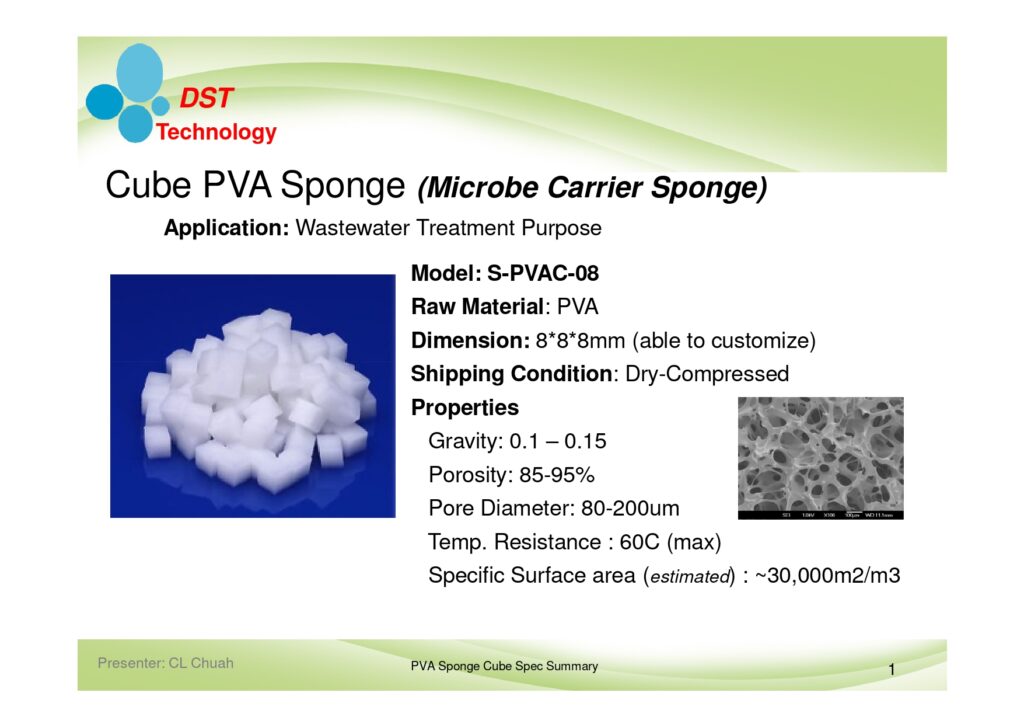

The growth process mentioned earlier is analogous to the functioning of an MBBR, which stands for Moving Bed Biofilm Reactor. Among various substrates, we have discovered that the PVA sponge cube holds significant promise in enabling microorganisms to thrive and establish an effective biofilm.

This is due to the coarse, interconnected porous 3D structure of the sponge cube, which provides an extensive surface area for microorganism contact and promotes their growth. Over time, microorganisms accumulate throughout the sponge, contributing to the development of the biofilm.

The MBBR Technology

MBBR technology represents an advanced approach in the treatment of industrial wastewater. Its primary concept revolves around fostering the growth of microorganisms and encouraging them to consume organic substances present in the wastewater. This, in turn, effectively reduces the Biological Oxygen Demand (BOD) in the wastewater.

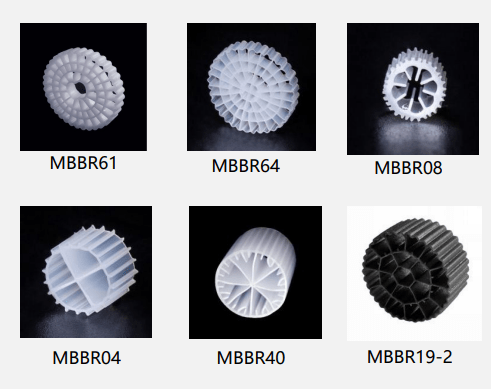

MBBR substrates are predominantly constructed from High-Density Polyethylene (HDPE). Structurally, they come in various shapes, all designed to serve as efficient carriers for microorganisms. The 3D porous patterns within these substrates provide a substantial specific surface area, facilitating the colonization of bacteria.

In other words, the specific surface area is a critical parameter for evaluating the effectiveness of an MBBR product.

PVA Sponge Cube for Biofilm Build-up

The HDPE MBBR is having specific surface area about 300m2/m3, however it is far less if compare with a porous sponge. For an ordinary PVA sponge cube, the specific surface area could reach 30,000m2/m3 or even more. The large specific surface area is due to the high porosity ratio as well as the small pore size.

The large specific surface area gives the PVA sponge an advantage to apply for replacing the MBBR in the wastewater treatment. The break through is remarkable and we are seeing more user is using the PVA sponge cube for building up the biofilm.

[…] pipelines and filtration systems, indicating a need for improvements in the overall process. We do promote microbe grows in wastewater treatment plant, however the grow in water pipeline would be a […]

[…] have positioned it as an advanced media for MBBR biochip substrates. In our earlier blog, PVA Sponge Cube for Developing Biofilm, we had reviewed the mechanism of biofilm formation. In this article, let’s delve into why […]