FAQ

Here we summarize some of the most frequently ask a question about PVA sponge roller. Hope it could clear some of your doubt.

How to determine the pore size of the PVA sponge roller?

PVA sponge roller is a porous substance. Perhaps it is an open pore structure which all the pore is inter-connected.

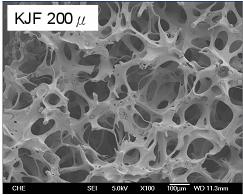

You could observe the porous structure by putting a cross-section of a PVA sponge roller high power magnification scope. In industry practice, the pore size is inspected and measure under SEM tools.

Enclosed is a cross-section magnification image with a 200um pore size which we snapped under SEM tools. The pore size can be determined with the scale that comes with the image.

How we clean the sponge roller before shipping?

Our PVA sponge roller will go through a series of the cleaning process to ensure the sponge roller is meeting the cleanliness specification. The PVA sponge roller will be clean with:

- Ultrasonic cleaning

- DI water soak and overflow cleaning

Should Customer clean the PVA sponge roller before use?

Even though the sponge roller is meeting a stringent cleanliness specification, however, we strongly recommend customer will go through a simple step of cleaning before use.

With the additional cleaning at customer site right before use is to ensure we only put the cleaning sponge roller in the cleaning line.

Even though we strongly recommend customer will go through a final cleaning before use but an individual customer could adopt the appropriate cleaning method that best fit for their process needs.

Below is some recommended cleaning procedure for reference:

- Dry stage sponge roller

- Soak the dry sponge roller in water solution.

- Wait until the sponge roller is softening.

- Drain the water in the sponge roller by squeezing the sponge roller.

- Repeat step 1), 2) & 3) if needed.

- Install in the process tool.

- Wet stage sponge roller.

- Soak the wet sponge roller in DI water.

- Drain the sponge roller by squeezing the sponge roller

- Continue Step A) & B) for 3-5 times before install in the process tool.

Or you could install a dedicate sponge roller cleaning machine for better result. DST does supply an individual sponge roller cleaning machine for your process needs.

What is the Cleanliness Specification We could Achieve

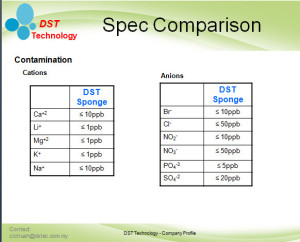

Our sponge roller is meeting very stringent cleanliness specification. DST know very well on customer process requirement hence we only supply sponge roller products meeting higher cleaning specification.

Our sponge roller will go through a stringent cleaning process as mention in the previous section, and our sponge roller will be a sample for Ionic Contamination test. Here is our sponge roller IC testing result.

Is PVA sponge roller suitable for my chemical solution?

PVA sponge is a material working in the wet process. The PVA sponge has many opportunities to work in various kind of chemical solution. There are several symptoms field engineers could observe and make a quick determination if the chemical solution is bringing adverse effect to the PVA sponge.

The sponge deterioration symptoms include:

- PVA Sponge Discoloration.

- Sponge characteristic change, such as the sponge is turning hard.

- Sponge peer off along the process.

The Foam and Sponge Cell

Even though the material may looks and feel spongy or foamy, but there are slight difference while come in differentiation. Foam and sponge serve two difference style for a material.

Both Foam and Sponge is a cellular structure if we observe under microscopy view.

- Foam Structure. Under microscope, the cell is “Open Pore” form. Means, all the cell is inter-connected. The inter-connected will act as a waterway so that the water could flow through easily.

- Sponge Structure. The cell comes in “Closed Cell” format. It means all the cell is not inter-connected. This makes the sponge becomes a good barrier for a liquid or gas. The liquid unable to flow through the cell because it is closed cell form.

The pore structure for PVA sponge is “open cell” structure. Since the industry is using “sponge” or “brush” through-out the communication, hence, we will remain the same practice for the terminology.

Leave a Comment