The Advance Biochip MBBR Media

- On Nov, 11, 2023

- admin

- Others, PVA Sponge

The PVA sponge’s unique characteristics have positioned it as an advanced media for MBBR biochip substrates. In our earlier blog, PVA Sponge Cube for Developing Biofilm, we had reviewed the mechanism of biofilm formation. In this article, let’s delve into why this shift has been occurring in industrial effluent treatment.

The MBBR substrates have a history of nearly 40 years since their inception in the industry. During this time, the development of microbe carriers was primarily focused on the physical structural design. However, in recent times, we have witnessed significant advancements in MBBR substrate material selection.

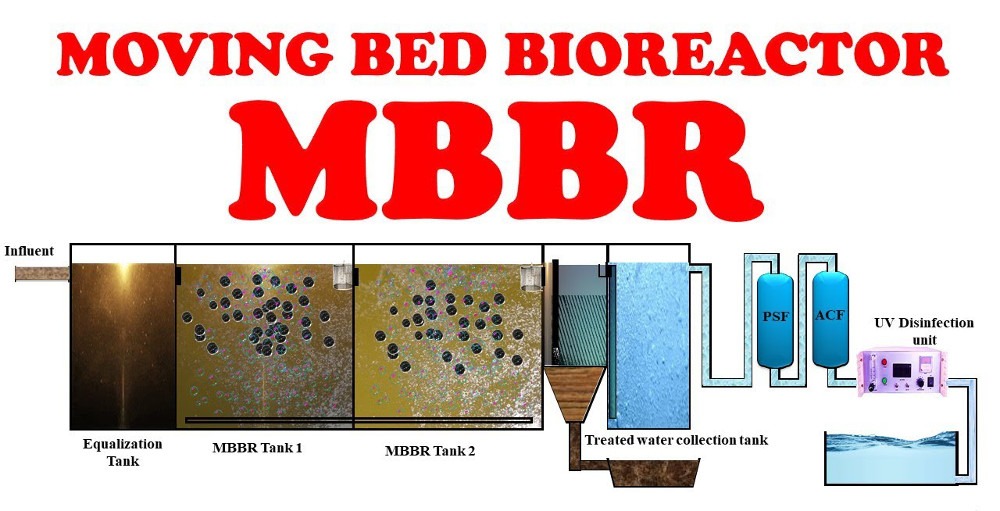

MBBR media is deployed in the aeration tank of the wastewater treatment process, serving as a carrier for microorganisms to facilitate biofilm growth. With the advent of PVA sponge material, we have observed an expansion of its applications into wastewater treatment.

PVA sponge has shown a good potential becomes a new media as biochip MBBR substrate.

Main Properties for Biochip MBBR Media

To become a reliable biochip MBBR media, several essential properties must be present, including:

- Hydrophilic in Nature.

- High Specific Surface Area.

- Interconnected Waterways.

- A Preferable Surface for Microbes to Reside.

The hydrophilic nature of the substrate is vital. Perhaps, it is a key property to become an effective MBBR media. The PVA sponge possesses excellent water absorption capabilities due to its interconnected open-pore structure. Additionally, its high porosity structure contributes to its hydrophilic nature. Without any additional effort, PVA sponge cubes can naturally float within the solution in the aeration tank. This provides an ideal environment for the colonization and growth of microorganisms and form a prosperous biofilm.

Furthermore, the floated sponge also give the biofilm a better position to remove organic contaminant evenly throughout the aeration tank.

Broaden the MBBR Media Selection

The application of PVA foam cubes as MBBR media in wastewater effluent systems is undeniably an innovative technology. This media has garnered various names in the industry, including:

- MBBR chip media

- Eco media

- Biochip MBBR media

Despite the diverse product names, they all serve the same fundamental purpose, which is to provide an innovative MBBR media for wastewater treatment.

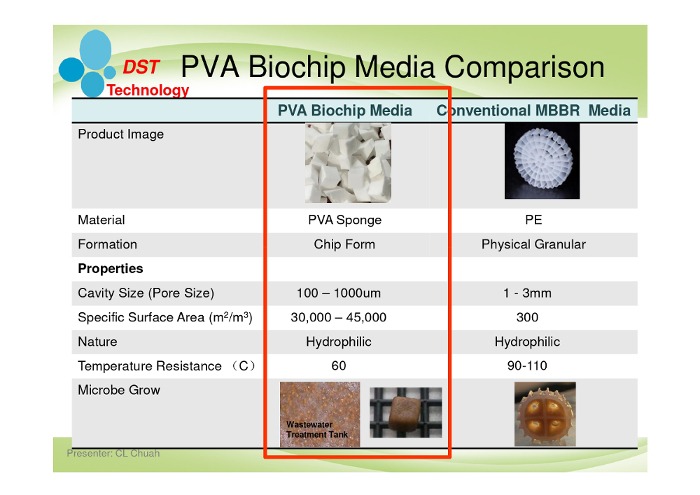

Comparison of MBBR Media

Conventional MBBR media is primarily constructed from PE plastic material, while the latest innovation, PVA sponge MBBR substrate, is made from PVA foam. It has been fully dried and compressed before shipping. Meanwhile, the PVA foam MBBR material offers several advantages:

- Ideal for microbe carriers.

- Lightweight with excellent buoyancy.

- Durable and long-lasting.

- Biodegradable, posing no additional burden on the aeration tank.

PVA foam represents an advanced biochip media for MBBR substrates.

This innovative technology in MBBR substrates has introduced new perspectives to the industrial wastewater effluent system. Evaluating and embracing the benefits of this new MBBR media is certainly a step forward. Feel free to contact DST for further information about this new biochip MBBR media.

Leave a Comment