More about PVA Sponge Cleanliness

- On Sep, 24, 2019

- admin

- PVA Sponge Roller

We know that PVA sponge roller is the commodity for the cleaning process, but how could we determine the sponge roller cleanliness? A contaminated sponge brush may not only unable to clean-up the substrate surface but also contaminated the cleaning process. This is the reason why only quality sponge roller could be used in the process.

DST has been working with many industries for supplying detergent and PVA sponge roller for their cleaning process. For instance, the hard disc drive industry and wafer cleaning are the two most stringent industries that require the highest requirement in sponge roller cleanliness specification.

Many industries have shown great concern about the PVA sponge cleanliness. Perhaps, they are also tightening up the cleanliness spec too!

PVA Sponge Contamination

During the PVA sponge manufacturing process, we have used several raw materials or ingredients. Hence, some of the process raw materials could be leftover in the PVA sponge roller. In order to clean-up those contaminants, we have set up a final sponge cleaning process to wash out those contaminants before packing.

Let us list down several contaminants that could be leftover in the PVA sponge prior to the final cleaning:

- Starch

- None reacted PVA particle

- Formaldehyde solution

- Foaming agent

We have a detailed study on our PVA sponge cleaning process. Moreover, the cleaning process is efficient to remove the contaminants left on the sponge during the manufacturing process.

Why Remove the Contaminants

Many PVA sponge manufacturers have overlooked the necessity of removing the contaminants from the PVA sponge. During a cleaning process, a contaminated sponge may transfer the contaminant from the PVA sponge onto the substrate surface.

DST has a dedicated sponge cleaning process to clean up our sponge after manufacturing. Once the sponge being cleaned, we will sample several PVA sponges for sponge cleanliness monitoring. Our PVA sponge roller will go through a stringent cleaning process as well as quality measurement to ensure sponge quality compliance before shipping.

The PVA sponge quality system has acted as the basis for DST to monitor our product quality to fulfil the most stringent cleanliness requirement.

Monitor PVA Sponge Cleanliness

There are several cleaning techniques and technology in our PVA sponge cleaning process. Apparently, the cleaning process is required to remove the contaminants leftover in the sponge. Many studies and development have been emphasized in the final sponge cleaning.

Parameters Monitoring

After the cleaning process, we will sample a few sponge samples for cleanliness measurement. During the monitoring, we will use several cleanliness monitoring tools to examine the sponge cleanliness data.

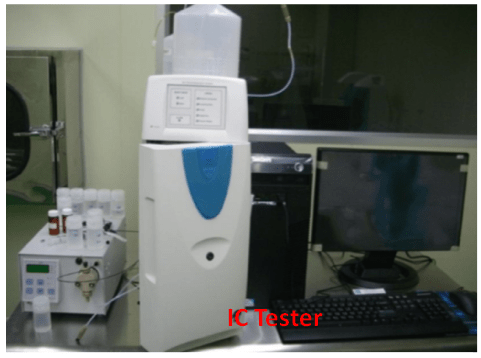

IC Test.

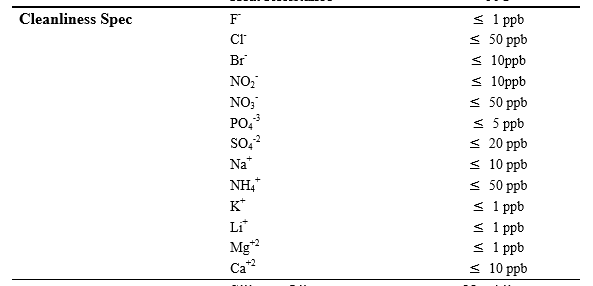

The IC stands for the Ion Chromatography test. This is the tool we used for determining the sponge fulfills the cleanliness requirement. The ppb ionic level is a good sign to indicate the sponge’s cleanliness.

LPC meter.

The LPC meter is used to measure the particle leach out count within a piece of sponge. For customer who is very particular on particle leach out, this tool could be the correct option. However, through our experience, we seldom bother too much in LPC count within a sponge. Our reader could read more insight into why we say so in the article why bother in LPC count.

Cleaning Process and Water Treatment System

Enforce a reliable cleaning process as a basis for ensuring PVA sponge roller cleanliness fulfills stringent criteria. While we mention a reliable cleaning process, we are referring not only to the cleaning process but also to the water treatment system.

DST always welcome our reader to leave your concern about pva sponge cleanliness, we will answer your concern accordingly based on our knowledge in this industry.

[…] Sponge cleanliness becomes more demanding in the process. We have to improve our sponge cleanliness in order to have the flexibility to use in various industries. […]

[…] More about PVA Sponge Cleanliness – PVA Sponge ImprovementSpecilize in Industry Cleaning Process says: March 1, 2021 at 2:24 pm […]