The Sponge for Precision Scrubbing

- On May, 13, 2023

- admin

- PVA Sponge

Precision scrubbing which involves PVA sponge is one of the important process in industrial surface cleaning. This is because the PVA sponge has to provide sufficient scrubbing force without causing scratching or damaging the substrate surface. Especially in the silicon wafers and hard disc substrate surface cleaning, those precision part require a good quality scrubbing sponge design to achieve the surface cleanliness requirement.

Perhaps, the sponge design is totally difference for precision scrubbing and industrial glass surface cleaning. The melamine sponge which we evaluate earlier ago definitely is not suitable for industrial surface cleaning. Even though the sponge may looks similar unfortunately there are a huge difference in term of key focus area.

Select the appropriate sponge design in order to achieve the surface cleanliness result.

The Precision Scrubbing Requirements

There are 2 important factors while come to surface cleaning, namely contaminant removal and avoid cross contaminant. Without in-depth consideration in sponge design, there are no way we could overcome and achieve the surface cleanliness.

Contaminant Particulate Removal.

In a precision cleaning process, the “dirty” substrate component shall go through several cleaning process such as soak clean with water overflow, ultrasonic cleaning, spray wash, but ultimately, the substrate shall go through precision scrubbing process and drying.

The PVA brush scrubbing provides an effective scrubbing force from the sponge asperity via

- Non-contact type of hydrodynamic dragging force.

- Contact mode via Van-Der-Waals force.

- Electrostatic double layer force (Gouy-Chapman-Stern model)

Maintaining a consistent sponge or brush asperity as well as the structural design are our goals to achieve in precision scrubbing process.

Ionic Contaminant.

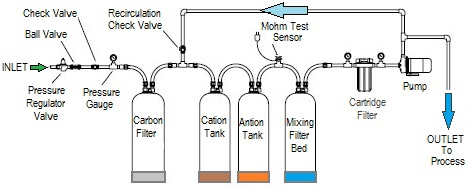

Many industrial engineers have neglected the importance factor of ionic contamination. Perhaps, maintaining an excellence water quality is the basic requirement of a cleaning process.

Takes DI water as an example for purify water, there are several ways for setting up a DI water system, so the field engineer has to select and setup an appropriate DI water system so that the water used during the cleaning process will not causing re-contaminate the substrate surface. This is because ionic contaminant is so important because the ionic in the water will becomes a generator for water mark.

For our precision scrubbing sponge, the sponge has to be cleaned in high quality DI water. Furthermore, the sponge has to be handled and packed in the clean room just to ensure meeting highest cleanliness requirement.

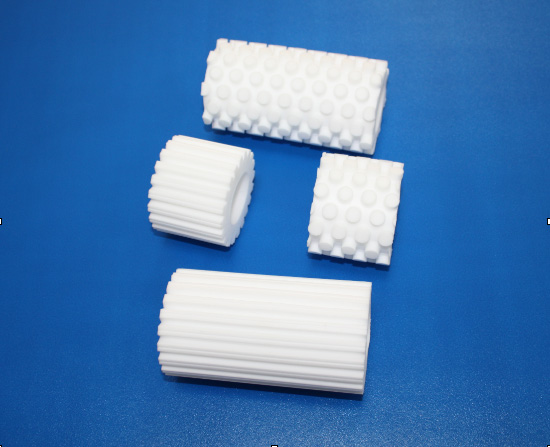

The Sponge Design

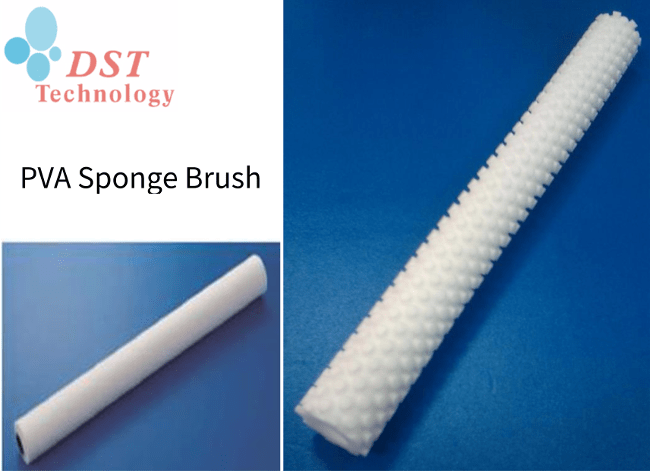

There are many type of sponge design in the market, all are design in such as way to achieve certain cleaning requirement. So far we have various kind of PVA sponge design for respective precision scrubbing process.

- Nodular sponge. Mainly used for surface cleaning.

- Spline roller sponge. Used for surface cleaning.

- Bevel Sponge. Use to clean the substrate chamfer area.

- Top brush.

Why To use Precision Scrubbing Sponge?

There are many type of PVA sponges or brushes in the market, it becomes confusing for the selection. You have to select the appropriate sponge if you are using for precision surface scrubbing. There are many details and engineering in order to develop a suitable sponge.

The engineering exposure and a profound cleaning knowledge is definitely a must in this sector. Feel free to contact DST in case you are facing challenge or want to improve the cleaning performance, we are always here to work together moving toward the new cleanliness regime.

Leave a Comment