The Dry PVA Sponge Roller

- On Feb, 25, 2021

- admin

- PVA Sponge Roller

We straight to the point, the dry PVA sponge roller will turn rigid and hard. This is the nature of PVA sponge characteristic which we have face every day.

The PVA sponge roller remains at a wet stage right after our manufacturing process. Perhaps, the PVA sponge roller shall use in the wet stage during the application process.

Some PVA sponge rollers shipped under the dry stage, so it is rigid and hard.

The PVA Sponge Roller Nature

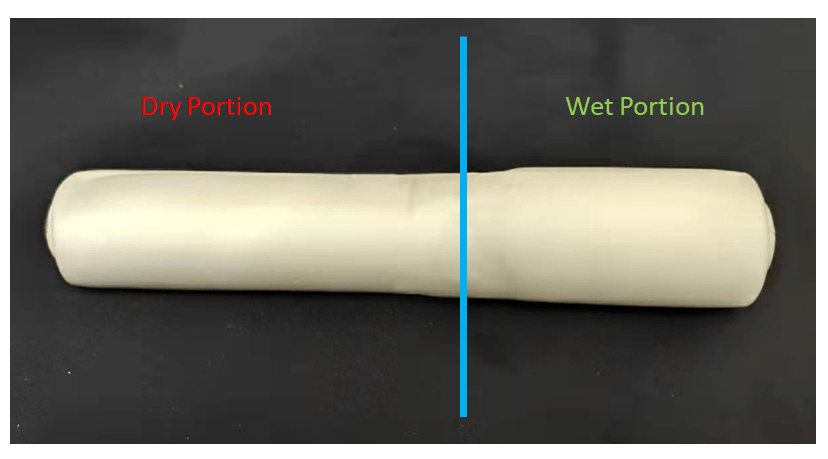

The PVA sponge roller will remain soft and elastic during the wet stage, however, the sponge will turn hard once dry off. Perhaps, the sponge will shrink once dry off.

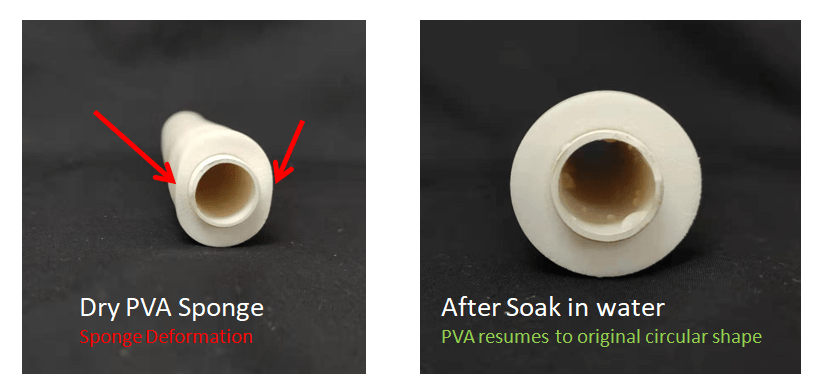

In addition, we also notice the PVA sponge will deform along the drying process. Such as the sponge lay flat during the drying process, hence you may see a flat surface in the contact area.

The sponge will resume to the normal condition once it has fully soaked. Furthermore, the sponge deformation and characteristic will be regained.

The Dry Sponge

We do receive calls from the user that the PVA sponge gets to dry off after the cleaning process stop for several days. In most cases, we always recommend the user could continuously apply water to the PVA sponge roller so that the sponge could remain at the soft and wet stage.

Wetting a dry PVA Sponge Roller

In case drying is inevitable, the correct procedure is to wet the sponge before resuming the operation. The Wetting Process may look something like this:

- Remove the dry roller from the cleaning machine.

- Soak the dried PVA sponge roller into the water.

- Ensure the PVA sponge roller is thoroughly wetted.

- Squeeze the accessive water from the PVA sponge roller but the sponge still under the wet stage.

- Install the wet PVA sponge roller on the machine.

Causing Damages

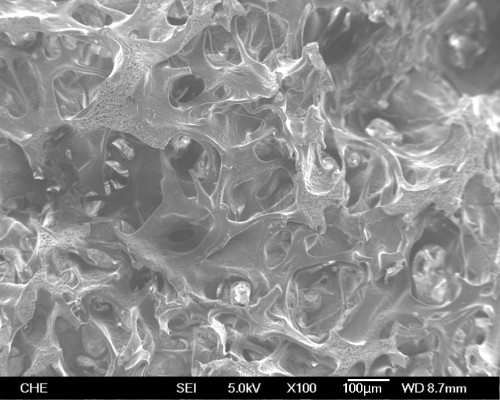

An insufficient wet sponge is unable to perform the cleaning process as expected. This is because of the shrinkage of the pore cell and the blockage of the waterway. Meanwhile, damage happens since the sponge is not fully wetted.

- Damage on Cleaned Substrate. Insufficient water-way in the PVA sponge may reduce the water flow on the cleaned substrate. This will cause poor water flushing effect. Furthermore, it may also cause scratches on the surface.

- Damage on the PVA Sponge Roller. The hardened surface will cause damage to the sponge.

PVA Sponge Shipping Condition

Semiconductor Industry.

The PVA sponge roller or the PVA foam wiper shall be shipped under the wet form.

PCB and other Industry.

Mostly ship under dry-form unless those big size roller.

You could let us know your packing requirement so that we could fulfil your needs. In general, the dry sponge is not a special case, it is natural for the material and you could further resume the dry PVA sponge roller with a thorough soaking.

Leave a Comment