Select the Non-Silicone Based Defoamer

- On Jun, 29, 2022

- admin

- Detergent, Others, Surface Cleaning

The non-silicone based defoamer becomes a scarcity product as most of the defoamer in the market are silicone based product. Even though the silicone based formulation is out-beating in performance, but there are always a niche market that the user has to select the non-silicone based product.

While we stir up a detergent solution, we are introducing a movement or energy that causing foam generation. Certain detergent which too rich in foaming performance will cause the foam growing faster than eliminating. Under this circumstances, the field engineer will apply defoamer to break up the growing foam to avoid overwhelm.

Field engineer has to select non-silicone based defoamer if the silicone is forbidden in the process.

Applying The Defoamer

As mention earlier, the defoamer is used as foam breaking purpose. In certain cleaning process, while the foam is overflowing at the drainage system, the field engineer will spray some defoamer on the foam surface to get away the growing foam. This is the most straight forward process. Unfortunately, most of the defoamer are formulated under silicone based.

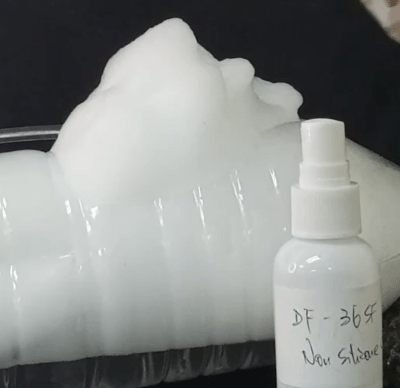

The NS Defoamer, is a dedicated formulation which consist NO silicone or silicone free from the ingredient. Some industry who having high level of surface cleanliness requirement, such as hard disc drive and semiconductor industry, they should be the customers looking for non silicone based defoamer.

Spray the Defoamer

In many case, we could bottle the defoamer in a spray bottle. Just pointing the nozzle and spraying on top of the upper part of the foam area. The foam will breaking up once get in touch with the defoamer.

If you are foreseeing a continuous application, you could install a diaphragm pump as an auto dosing system. The auto dosing system shall spray a fix amount of the defoamer within a time interval. This will help the field engineer to avoid foam overflowing from drainage. Select an appropriate nozzle as suitable to your application.

Why Non-silicone Based Defoamer

Not only defoamer consists of silicone, but also other products such as coolant, de-mold agent. This cause some level of silicone will transfer to the product. Even though the transferred silicone trace comes in small amount but the impact is huge. For instance, the silicone contaminant staying on the product surface will cause failure in sputtering process. The detrimental product failure will eventually affect the product quality.

In many processes which require high surface cleanliness expectation, the field engineer always avoid silicone contaminant. Under this circumstance, non-silicone based product becomes the scarcity choice if not the only choice.

Parameter to Select a Defoamer

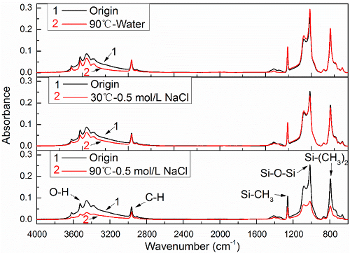

There are a few criteria we could adopt while selecting a non-silicone based defoamer product. The first mandatory condition is checking the silicone trace in the defoamer. Besides reading the material ingredient list from the manufacturer, the user could send the defoamer sample to a Material Science Lab performing a FTIR spectrum test to identify the existence of Silicone trace.

Besides the ingredient, now we could physically check the defoamer performance from 2 aspects.

- Foam Breaking Speed. The foam shall break up once get contact with the defoamer. Observe the foam break-up speed.

- Effective Defoaming Duration. The defoamer shall spray on the foam area and the defoamer shall be effective to carry out the foam break-up activity. Observe the effective duration after the spray.

Defoamer Performance Comparison

Even though we have formulated the NS Defoamer in full force, but there are always a limitation. In term of product performance, the silicone based formulation still better than non-silicone based.

The silicone base formulation is better in foam break-up speed and effective duration. Whereby, the non-silicone based defoamer is meant for process which requires silicone free.

With the launch of NS Defoamer, we are very proud that the market is having another choice defoamer products. Feel free talk to DST if you are facing challenge in removing silicone based product from your process.

Leave a Comment