PVA Sponge Visual Deficiency

- On Jun, 15, 2022

- admin

- PVA Sponge, PVA Sponge Roller

Today we are going to talk about PVA sponge visual deficiency. As a PVA sponge supplier, we are seeing many PVA sponge rollers, either our own product or from other suppliers. We would like to take this opportunity to summarize some visual defects on the PVA sponge.

Even though PVA sponge comes in various form but they are sharing a similar visual defect. We will discuss several common visual deficiencies here.

There are several PVA sponge visual deficiencies, such as discolouration, bubble void and tear off.

PVA Sponge Visual Deiciency

Visual is the most straightforward way to determine a sponge quality. While you receive the PVA sponge, just spend a fraction of time simply looking around the sponge, your intuition will tell you how good the sponge quality looks.

A quality sponge will be a homogenous substance, any alien material embedded in the sponge should consider as a deficiency. Besides the alien material, we will discuss the two visual defects which happen on the PVA sponge.

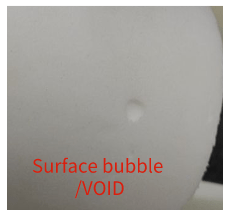

Bubble or visual void

The PVA sponge is manufactured via a chemical forming process and the bubble is generated during the foaming process. A quality sponge already refers to a uniform foam structure throughout the sponge. Whereby, an improper foaming process will lead to more large bubbles or voids on the cross-section.

During a foaming process, the air trap shall be released so that to reduce inconsistent large bubbles. But there is always some air trap that is unable to escape during the foaming process and turn out to be a bubble defect. Furthermore, the bubble most likely happens in the side area.

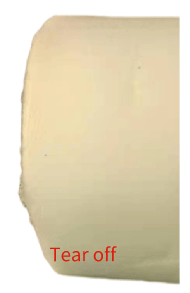

Surface Tear Off

An original PVA sponge comes in a larger size, and it will send for edge trimming to the exact size. During the trimming process, we may encounter a tear-off mark if the trimming process is deficient.

In general, bubble and minor tear-off marks may not cause detrimental defects on sponge quality. However, it provides an indicator of how we monitor our entire PVA sponge manufacturing process.

Sponge Discolouration

PVA sponge is a durable product and able to withstand many rounds of cleaning. However, the product will start to deteriorate after the life cycle is reached. Sponge discolouration is always the first symptom to show the product is deteriorating. Our industrial uses PVA sponge comes in snow-white colour, and it will turn light yellowish after aged.

Furthermore, the sponge may start to decompose after it turns yellowish. You will start seeing some particle dropoff from the sponge while it starts decomposing.

In this article, we are sharing with you several PVA sponge visual defects or deficiencies so that we could make our own judgement for any PVA sponge roller. You are not necessary only to examine with expensive apparatus, even with a simple visual inspection, you are able to differentiate the sponge quality.

Leave a Comment