PVA Sponge Pore Structure

- On Aug, 24, 2019

- admin

- PVA Sponge Roller

In last article, the PVA sponge foaming know-how, we had discussed the pore morphology is affecting by the foaming process. We want to talk about the pore structure so that our reader could have better understanding sponge properties.

Sponge Properties – Pore Structure

PVA sponge is porous material which constructed by pore structure. There are several parameters we normally used for illustrate a porous material, such as:

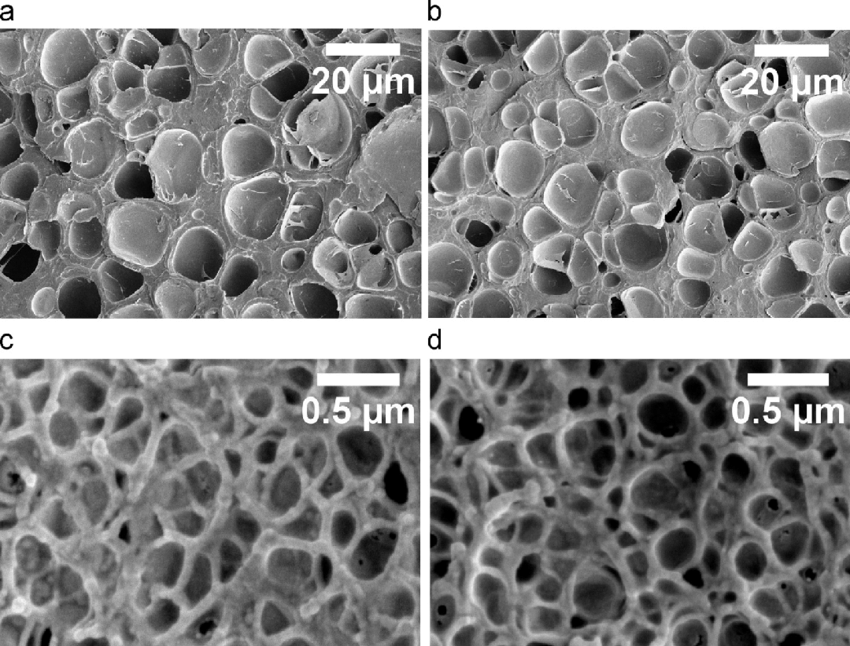

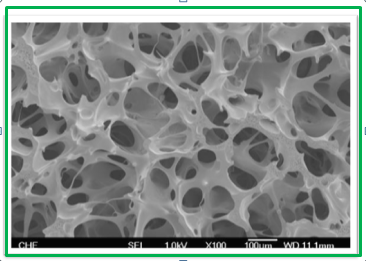

- Pore structure. There are 2 kinds of pore structure which is open pore and close pore. The porous in PVA sponge is an open pore structure.

- Pore size. Pore size is the parameter use to descript the pore dimension. Even though porous structure is not coming in circular pattern, but we are still able to measure the longest distance for individual pore to determine the pore size.

- Porosity ratio. Within a fix size of sponge material, porosity is using to illustrate the % ratio has been occupied by the sponge structure. In lay man term, a high porosity always leads to more spongy effect.

With the above 3 parameters, we could mechanically understand a structure for

What is Pore Uniformity?

In a porous material, we emphasize the pore size, such as 160um. Since porous process is controlling by a foaming process, and it comes with irregular shape, the pore structure consistency becomes a challenge for PVA sponge manufacturer.

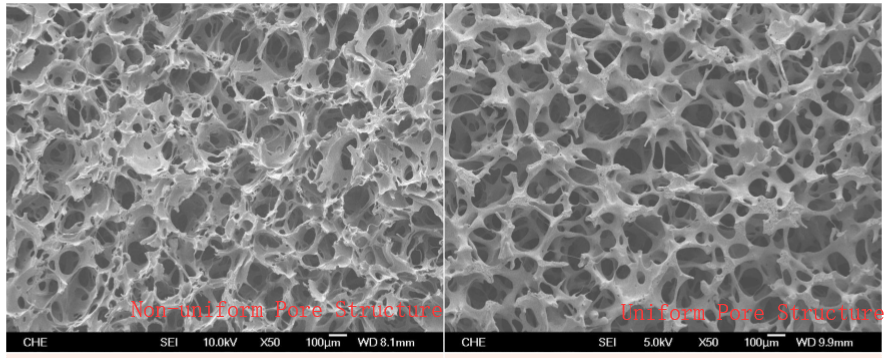

By looking at the cross

Not Uniform Pore Structure

If we look into microscopic view under SEM, a poor quality sponge come in non-uniform pore structure will lead to uneven pore size or random pore structure. Nonuniform pore structure will lead to two extreme

- No porous area. In the magnified image, we could easily see some of the cross

– section which is not properly grown. This is due to insufficient foaming at this area. The micro view for this area will have a significant difference compared to others, such as: - Insufficient water flow through rate

- Surface is harder

- Larger pore structure.

A larger pore structure area may cause inconsistent in mechanical properties as descript earlier.

So far we have revealed the parameters to illustrate a porous material and the pore uniformity in a porous material. These are all the micro view

Leave a Comment