Detrimental Effect for Non-uniform PVA Pore Size

- On Aug, 31, 2019

- admin

- PVA Sponge Roller

PVA Foaming is the important process for making a quality PVA sponge. In earlier article, we had discussed the parameters which affected the foaming process, furthermore, we also talked about the importance for maintaining a uniform pore size and pore structure. In this article, we are going to reveal the detrimental effect due to non-uniform pore size.

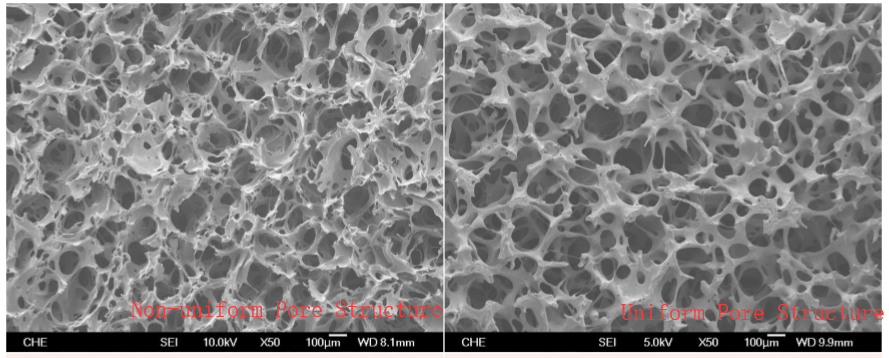

Non-uniform Pore Size

Above image is a cross-section for a PVA sponge roller. From the SEM image, you could notice that some portion of the sponge surface has insufficient foaming structure. We could claim that this PVA sponge comes with inconsistent pore size. The inconsistency or non-uniform pore size may not

What are the Incompetent for Non-uniform Pore Size?

In a cleaning process, the PVA sponge roller plays an important role from 2 aspects:

- Delivered mechanical force for removing the contaminant.

- Promote water flow to flush the loose particle.

The area with no foaming will affect cleaning performance. The water flow rate may become insufficient at the area and causing a variant on cleaning efficiency. Due to less or no water flow way at the area, the contaminant generates from the process is tend to stick on the surface. After some time, the sponge will pick up and accumulated more contaminant at the no foaming area.

Detrimental Effect for Non-uniform Pore Sponge

Because the non-uniform pore structure is so small and unable to recognize unless a detail and scrutiny examination being carried out. During the process failure analysis, the field engineer may encounter several sporadic defects occurrences which do not have clear cut relation to root cause, such as:

- Sporadic contamination spot

- Surface scratch

This is the opportunity for us to study the PVA sponge’s pore morphology and pore uniformity. In most cases, with the help of SEM or magnification tools, we are seeing more contaminant clog up in certain area instead of other area.

In many occasion, user may not able to appreciate a uniform pore size PVA sponge until you come across a critical moment. DST is always proud of our PVA sponge and we believe our experience in the cleaning process will definitely improve the cleaning yield. DST is always here to work with you to improve your cleaning performance. Feel free contact DST for your needs.

Leave a Comment