Understand Surface Contaminants

- On Oct, 07, 2012

- DST

- Surface Cleaning

We had discussed about the basic of wet surface cleaning process, before we come to the exact detergent selection for contaminant removal, we would like to reveal some aspects to understand surface

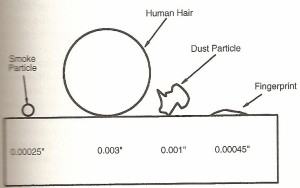

Various Size of Contaminant

contaminants.

Contaminants or contamination generate during the manufacture process will cause rejection and product degrade in quality and reliability. Understand the surface contaminant rested on the substrate surface is the first step before setting up a reliable wet surface cleaning process. Field engineer requires monitor and analyze the contaminants in order to fully understand the surface contaminants involve.

The important of Surface Cleaning

Improving a cleaner products surface is a never ending continual process for field engineer. In many product lines, cleaning process has become the important station that directly affects the product yield and quality. Field engineer requires working with cleaning expert to find better and efficient way developing next generation cleaning process for removing contaminant rested on the substrate surface.

In general, wet cleaning process always brings better cleaning result to the product.

Category of Surface Contaminants

Particle Contamination

Particle could refer to the process left over or airborne particle floating in the air. Field engineer should examine and trace source of the contaminant. Difference type of contaminants may have their unique characteristic or signature which field engineer could identify with the help of tools.

In semiconductor industry, metallic contamination is one of the top hitter of contaminants. The metallic contaminant may have direct impact on product quality and causing reliability issue.

For instance an alkaline metallic contamination may cause MOS instability which adversely affected the device performance.

Chemical Contamination

This refer to the chemical residue on the substrate surface, the chemical contaminants could appears as a thin oxide film coated on the substrate surface. Chemical contaminants may lead the fail of IC, NVR or GCMS test.

Bacteria Contaminant

We do see bacteria growth in the piping and machinery edge with insufficient cleaning; those bacteria contaminants will eventually contaminate the products. Field engineer should pay extra attention in the area that contact with water.

Cause of Surface Contamination

From quality fish-born diagram, the surface contaminants could contribute from 5 aspects.

Human.

Identify the contaminant contribute by process operators.

Machinery.

The contaminant may contribute from machinery, piping, jigs.

Material.

The contaminant may contribute from raw material, process material, air quality & water quality.

Method.

Review the material handling process, tools which may expose to contaminants.

Environment.

Check the environment contaminant level to ensure the process is carried out in an adequate working condition.

In order to identify the source of surface contaminant, field engineer should perform a thorough check in the process line and setup in order to identify the possible cause for generating the surface contaminant.

Feel free to discuss with DST Technology on your cleaning needs and we could work with you to establish better and reliable cleaning process.

[…] ought to establish a set of cleaning strategy while dealing with surface contaminant removal. During a detergent development process, we have to start from the fundamental to ensure appropriate […]