- On Apr, 27, 2019

- admin

The user wants to know about the PVA sponge roller life span, this is one of the frequently asked questions. DST is a sponge roller supplier in the cleaning industry, we are very concern about the sponge roller we supply, we do determine our sponge roller life span so that our user could have a […]

- On Apr, 16, 2019

- admin

DST is able to tailor made the PVA sponge roller to cater for your dedicate process dimension. Our process is so flexible that we do not limit the PVA sponge roller dimension. The tailor-made ability will definitely bring advantages for our user however it also comes to a stage that how we could come out […]

Continue Reading...- On Nov, 04, 2018

- admin

PVA sponge roller is the common cleaning commodity used in many cleaning processes, ensure the PVA sponge roller cleanliness becomes more critical in recent cleaning needs. DST understand customers’ need and supplying quality PVA sponge roller becomes our primary goal through-out our organization. Basic of PVA Cleaning Process Our PVA sponge roller all clean in […]

- On Oct, 28, 2018

- admin

PVA Sponge roller seems a common sponge product in the market, there are some PVA sponge mechanical properties to illustrate the products. While we are promoting our PVA sponge roller products to the market, we would like to educate our users the appropriate testing equipments used to measure respective mechanical properties. Mechanical Properties Below is […]

Continue Reading...- On Nov, 10, 2017

- admin

DST has consistently supply high quality and consistent PVA sponge roller product for semiconductor, electronic and PCB process. Many customers always curious about our knowledge and commitment toward cleaning process, the main reason is, we are proud of our PVA sponge roller. Knowledge on PVA Sponge DST has focus in cleaning industry for 5 years. […]

- On Oct, 23, 2017

- admin

Through-out our application with PVA sponge roller, one of the common question from field engineer is “How to determine a PVA sponge life span? “ Here we would like to share with our reader about several perspectives which field engineer could consider while determining the PVA sponge life span. We welcome all comments if you […]

- On May, 07, 2015

- admin

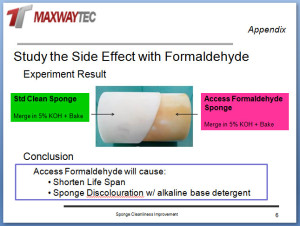

In our previous article, we know from our reader saying that they are interested to find out the impact on sponge roller with high Formaldehyde left over. In this article, we will not explain the impact on formaldehyde from chemistry equation; we rather share with our reader on a simple experiment we carry out on […]

Continue Reading...Improve Sponge Roller Cleanliness

- On Mar, 31, 2015

- admin

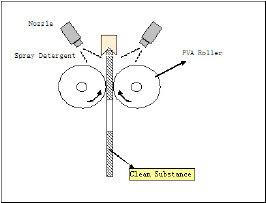

DST is supplying quality PVA sponge roller products. Our sponge roller is achieving a stringent cleaning specification, this is reason our sponge roller is widely used in many industries. Today, we are going to share with you some insight about our sponge roller cleaning process. Dedicate Sponge Roller Cleaning Machine After PVA sponge forming and […]

Continue Reading...- On Jul, 26, 2014

- admin

DST Technology commits in surface process cleaning. We have achieved many remarkable achievement through-out our company development. DST Technology is a Malaysia company however we do not limit ourselves from geography limitation. We are serving many Malaysia companies for their cleaning process improvement, on the other hand, we also working with several customers in overseas […]

- On Jun, 27, 2014

- admin

DST Technology commits in surface process cleaning. We have achieved many remarkable achievement through-out our company development. DST Technology is a Malaysia company however we do not limit ourselves from geography limitation. We are serving many Malaysia companies for their cleaning process improvement, on the other hand, we also working with several customers in overseas. […]

Continue Reading...