- On Nov, 16, 2012

- DST

PVA sponge roller is used in many wet surface cleaning process. Hard disc substrate and wafer cleaning process are the 2 cleaning processes that require high quality PVA sponge roller products. Perhaps PVA sponge roller design could play a very important role for achieving better cleaning result. Once a wet surface cleaning process has been […]

Continue Reading...- On Nov, 04, 2012

- DST

After understanding the surface contaminant and detergent selection, now is the time for us to set up a wet surface cleaning process. CMP process for wafer and hard disc substrate is one of the highly demanding processes and the subsequence surface cleaning process does play an important role in overall yield. The wet surface cleaning […]

Continue Reading...- On Oct, 27, 2012

- DST

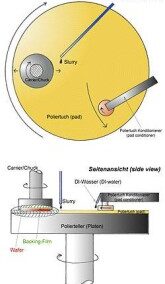

Chemical-Mechanical Planarization (CMP) process is the polishing process used in wafer and disc drive industry. Many efforts have been discussed on setting up an appropriate CMP process however not emphasizes being given on post-CMP cleaning process. In order to achieve a better surface appearance, CMP engineer should consider both the polishing process and post-CMP cleaning […]

- On Oct, 17, 2012

- DST

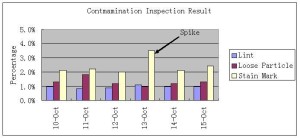

We have discussed several topics about surface cleaning process and contamination in previous articles. In this article, we would like to discuss something about establishing contamination inspection and setup monitoring scheme ensures the surface cleanliness. Surface contaminant will cause yield impact and reliability to the products such as the process involve surface coating, the […]

- On Oct, 08, 2012

- DST

After understanding the visual and contamination defect, now we need to setup a surface visual defect inspection system in order to detect the surface defect and particulate contamination. There are many type of surface inspection methods, system and equipments available in the market which field engineer could select. In this article, we are going to […]

- On Oct, 07, 2012

- DST

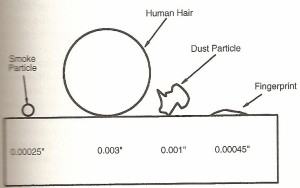

We had discussed about the basic of wet surface cleaning process, before we come to the exact detergent selection for contaminant removal, we would like to reveal some aspects to understand surface contaminants. Contaminants or contamination generate during the manufacture process will cause rejection and product degrade in quality and reliability. Understand the surface contaminant […]

- On Oct, 02, 2012

- DST

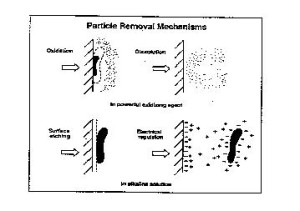

Surface cleaning is becoming more critical and stringent in many industries cleaning process, this include wafer surface cleaning process and hard disc drive surface cleaning. The main objective of surface cleaning is removing small particulate and left over on the substrate surface. The particulate mainly come from previous process such as abrasive and sludge. Field […]

Continue Reading...- On Jul, 24, 2012

- DST

We have discussed about the fundamental elements field engineer could adopt for setting up precision cleaning technology for cleaned substance. No matter which cleaning technology is selected, cleaning detergent is a mandatory commodity for cleaning process. DST Technology is one of the important detergent suppliers in Malaysia. Through out our detergent formulation and evaluation with […]

Continue Reading...- On Jul, 14, 2012

- DST

While we are enjoying many technical gadgets, do you ever think about the contribution from field engineer who works day and night to break through the technical barrier? Among the technical barriers, the improvement in precision cleaning technology is ever since that important as before. From our interactive with many Hi-Tech factories, not surprise to […]

- On Jul, 10, 2012

- DST

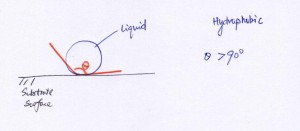

Contact angle is the importance parameter for judging a surface whether it is a hydrophilic or hydrophobic surface. In most cleaning process, the contact angle we are referring to is between solid-liquid-vapour. Solid refer to the cleaned substance. What is Contact Angle? The contact angle is the angle between the cleaned substance and the […]

Continue Reading...