Why PVA Roller Brush suitable for Post-CMP Cleaning Process?

- On Oct, 06, 2011

- DST

- Others, PVA Sponge Roller

Overview of PVA Roller Brush

PVA sponge is a soft, flexible and porous material; it could be formed to various physical pattern bases on the mold design and application. PVA sponge that comes with roller design is named as PVA roller.

PVA roller is having the basic characteristic property of excellent water absorption, soft and best resilience, it has becomes a suitable material used for cleaning material, which bring no harm on the clean substance.

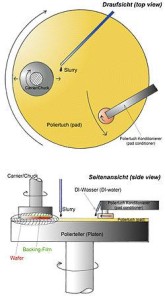

CMP Process

CMP process is the process involves Chemical-Mechanical effect during a planarization process. The substance surface will always covered with slurry abrasive, organic residue and ionic contaminate. Those particulate left over on the substance surface should be cleaned by the subsequence cleaning process or post-CMP cleaning.

PVA sponge roller – Importance Post-CMP Cleaning Tools

Post-CMP cleaning accompany with several cleaning tools and chemistry. PVA Roller Brush was initially introduced by IBM for industrial use as early as 1990s. In particulate removal, the soft and flexible nature of PVA Roller Brush has becomes a suitable material to give direct contact on the clean substance surface without damaging the surface. Through PVA Roller Brush scrubbing during the post-CPM process, the pore structure of the PVA Roller Brush capture the particulate from the clean substance.

Select the appropriate PVA sponge roller

Cleaning field engineers could select difference porous structure on the PVA Roller Brush for their specific contaminant particulates. With the DI Water and detergent fluid, many contaminant particulate could be effectively removed.

Certain dedicate cleaning mechanism requires additional coating on the PVA Roller Brush to enhance the repulsion effect between PVA Roller Brush and particulate contaminants, hence no particulate deposit on the PVA Roller Brush surface and it would reduce the scratch defect cause by the post-CMP process.

Reader are encourage to read our article about The Criteria for Selecting a PVA Roller.

Dedicate design of PVA Sponge Roller

Cleaning performance is related among chemical, mechanical and stability of the PVA Roller Brush. Many studies have been carried out for difference tribology design on PVA Roller Brush in order to maximize the cleaning ability. This will also further enhance the consistency of frictional characteristics as well as extend PVA Roller Brush lifetime.

PVA Roller Brush tribology design involve the pore structure design, strength, hardness and also mechanical outer profile, all these improvement is the factors to ensure consistent cleaning result.

Leave a Comment