Testing Equipment uses for PVA Sponge Mechanical Properties

- On Oct, 28, 2018

- admin

- PVA Sponge Roller

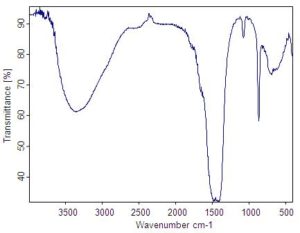

PVA Sponge roller seems a common sponge product in the market, there are some PVA sponge mechanical properties to illustrate the products. While we are promoting our PVA sponge roller products to the market, we would like to educate our users the appropriate testing equipments used to measure respective mechanical properties.

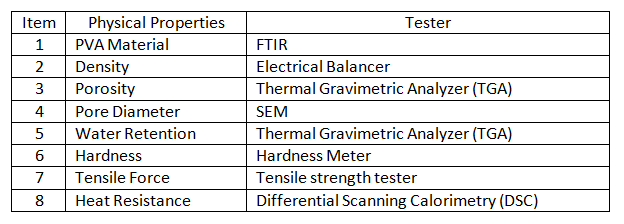

Mechanical Properties

Below is the summary table about the tester use for respective physical parameters.

As a sponge manufacturer, we do not own most of the above mechanical tester as the testing equipment. That means we have to rely several outsource laboratories in order to perform the above mechanical properties test. Furthermore, it may takes 2 weeks time in order to complete entire test.

Because of long time taken and comprehensive testing, hence we are unable to use the mechanical properties for buying off the lot. Not only that, it is also very costly in order to complete the entire mechanical properties test.

How Often to Measure the Mechanical Properties

On the other hand, even though we do not measure the above mechanical properties from every lot basic, but we know that the above physical properties are determined by the formulation recipe during the foaming process.

A better Key Process Input Parameter (KPIV) control is more important from our experience. There are several KPIV for material blending and foaming process, this include the temperature, pressure, viscosity control. From our experience, we are able to achieve consistent sponge roller product via controlling these set of KPIV parameters.

Parameters Affecting the Product Quality

We could elaborate a quality product by reviewing the information from 3 aspects:

- Mechanical dimension

- Cleanliness specification

- Mechanical properties

Mechanical dimension basically is controlled by the mold and the mechanical properties are very much depends on the foaming formulation recipe. Cleanliness specification is the most critical criteria on judging a sponge quality. A sponge without a good cleanliness specification will eventually bring reverse effect on cleaning process; we shall talk about the sponge cleanliness concern in separate topic.

If user is really particular with the mechanical properties on PVA sponge, instead of measure the entire set of properties, we would recommend we look into the hardness reading. Why hardness? An appropriate sponge foaming quality shall lead to dedicate sponge hardness. A harden sponge or soften sponge shall imply that the foaming process is deviated from norm. This monitoring will be more practical from manufacturing stand point.

Now you have better idea about the mechanical properties for PVA sponge roller as well as the equipments use for examine individual parameters. You are welcome to leave us your query or doubt to clarify the about sponge’s physical properties.

Leave a Comment