Sponge Roller Products

The PVA Sponge roller product is a common commodity used in many cleaning processes. In DST, we supply various sponge roller products such as PVA sponge roller and PVA brush in order to achieve better cleaning purposes. Besides the PVA material, we also supply other materials such as PU and PVC sponge. Meanwhile, we also provide customization PVA sponge service.

There are many types of sponge roller materials available in the market, it also comes in different design. This is because every process has its unique requirements. Due to the differences in chemical, temperature, and process requirement, hence we have to select the appropriate sponge material to fulfill the needs.

There are several type of sponge materials, such as PVA, PU, PVC, PO and much more. Among the material, PVA sponge is the most common material used in industrial cleaning process.

Sponge Roller Products – Material Variety

A demanding cleaning process may require many types of sponge materials in order to achieve the cleaning result. There is no one fit for all types of sponge material which suits all types of the cleaning process. Under this circumstance, sponge selection becomes a great challenge.

Furthermore, in order to achieve the best cleaning result, the cleaning field engineer shall discuss and evaluate several types of sponge rollers before making a conclusion. In DST, we familiar with the surface cleaning process and entire qualification procedure. We are open-minded and willing to work with field engineers on an appropriate sponge material selection.

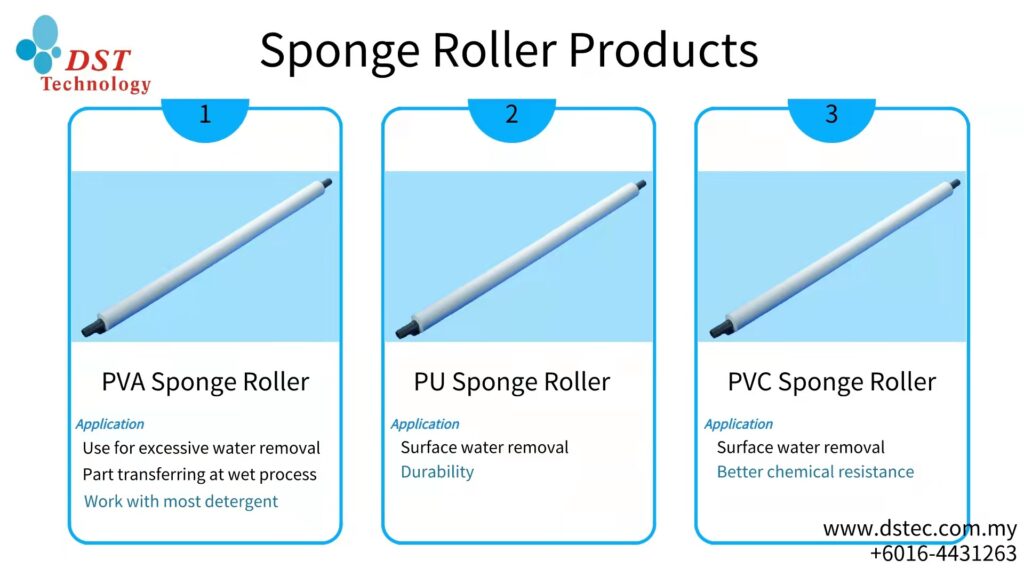

There are several types of sponge materials in our product list. Below are the 3 common types of sponge rollers material.

- PVA Sponge. The PVA sponge is the common sponge material which able to work with many detergents. Many cleaning processes use PVA sponge material.

- PU Sponge. PU sponge is commonly seen in some cleaning processes. This sponge delivers good durability.

- PVC sponge. PVC sponge comes in good water suction ability and is also a good choice if the user wants a chemical resistance sponge roller.

The Sponge Roller Application

For most of the cleaning process, the roller mainly used in these 3 applications:

- Surface excessive water removal

- Surface cleaning

- Part transferring in wet condition

A circular type of sponge roller is good for the above application. But on some occasions, the process requires some dedicated structure design to carry out the cleaning performance, especially the process requires better surface cleanliness.

The Sponge Structure

In DST, we provide customize PVA sponges for the customer who needs more about structural change. For instance, the PVA brushes below are sponge structure which we design for a dedicated customer.

- Nodular sponge

- Spline sponge

- Block sponge

- Irregular shape base on customer needs

Micro-structure Design

Apart from the sponge structure and material, we also able to fine-tune the sponge micro-structure and properties in order to fulfill a specific requirement. This is because we have to fine-tune the sponge properties so that the sponge is able to deliver some effects.

For a demanding customer, we could customize base on the below parameters, such as

- Sponge hardness

- Sponge pore size

- Improve sponge cleanliness

Let us know your cleaning requirements and process needs, we are always here to work with you to improve your process cleanliness requirement. Please kindly contact DST Technology to understand more about the sponge roller products we supply.

You can also see our relevant sponge products ppt in below slideshare presentation channel.

[…] Sponge Roller Products […]