Chemical Polish Process Setup

- On Apr, 23, 2012

- DST

- Chemical Polish

A metal alloy after gone through machinery process, the metal surface always left with machinery marking or trace. In order to eliminate machinery marking, field engineer will perform chemical polish for the metal alloy for achieving shinny and brighter alloy surface.

However there are some reminders for field engineer to remember while setting up the chemical polishing process.

The chemical polish solution

Make sure the chemical polishing solution is best suitable with the metal alloy for the substrate. For instance the chemical polish solution use for a 300 series stainless steel is total difference than for the chemical polish solution for anodizing of aluminum alloy.

Optimizing of Chemical Polish Process

The chemical polish solution always come with a standardize Technical Data Sheet (TDS). Field engineer will make use of this TDS as the start up of the process setup, this include the temperature, soaking time and agitation.

After obtaining the polish result, field engineer should carry out the optimization process to adjust the process parameter in order achieve the optimum condition.

Cleaning process after Chemical Polish

The metal alloy substrate requires going through a substantial amount of cleaning after the chemical polish. This is to ensure no chemical polish solution residue left on the metal substrate surface, especially at the inner groove area.

Let us take the DCP solution for stainless steel as an example. After the metal alloy soak in the chemical polishing solution, the stainless steel substrate should go through a substantial water rinsing process to ensure the chemical is thoroughly removed.

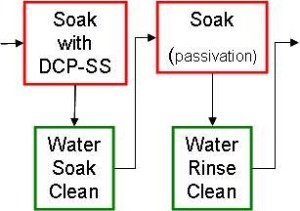

For more demanding user, field engineer will further soak the clean stainless steel substrate in a mild alkaline solution to form a passivation layer to improve and sustain the substrate quality. Please refer to the DCP soaking and passivation process flow as enclose schematic diagram.

Cleaning process at post polishing process is always a critical process that field engineer should not over look, meanwhile field engineer could add a passivation soaking for extending the substrate quality.

Non-electrical chemical polishing is a straight forward process; field engineer should able to obtain an acceptable surface finishing result by selecting appropriate chemical polish solution as well as determine the suitable process setup parameters.

Field engineer could also add a passivation soaking right after the chemical polish soaking to maintain the substrate surface quality.

DCP series of chemical polishing solution is a wide series of chemical polishing solution cover for stainless steel to aluminum substrate. Feel free to contact DST Technology to allow us working with you for improving the substrate surface quality.

[…] is another common method if you want to get an uniform surface. For metal surface, most of the chemical polish solution is mainly formulated under phosphorous acid base but we could use alkaline base in certain […]