- On Feb, 04, 2023

- admin

Similar to many plastic material, the PVA sponge has shown good chemical resistance performance for most of the chemical. The good chemical resistance is referring to the sponge roller does not has significant impact in product life span. Unfortunately, there are several chemical or acid solution are actually deteriorating the PVA sponge quality, for instance […]

- On Jan, 07, 2023

- admin

Improve the PVA sponge quality is definitely our goal. Before we are going through the details, we would like to take this opportunity wishing our business partners and customers for a happy and prosperous new year. Meantime, we reveal our new year resolution so that we could align ourselves with our customers’ requirement. As comments […]

- On Jun, 15, 2022

- admin

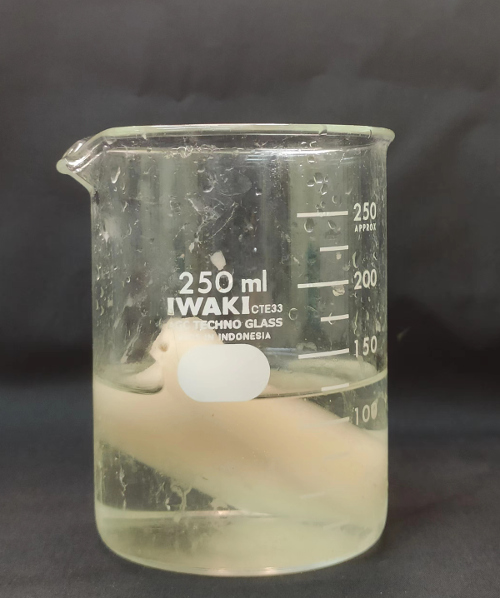

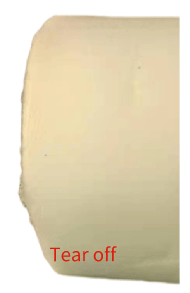

Today we are going to talk about PVA sponge visual deficiency. As a PVA sponge supplier, we are seeing many PVA sponge rollers, either our own product or from other suppliers. We would like to take this opportunity to summarize some visual defects on the PVA sponge. Even though PVA sponge comes in various form […]

- On Mar, 18, 2022

- admin

Many aware that the PVA sponge does expand after retains with water but not many discussed about the expansion rate. Even though the PVA sponge will expand after fully soak in water unfortunately not many talk about the expansion rate. The pore shrink at dry form, once the pore is filled with water, the entire […]

Continue Reading...- On Jul, 24, 2021

- admin

An industrial sponge roller could be much longer and larger in diameter. So far the PVA sponge roller looks in decent size, something like 50mm diameter with a length of 400-600mm. But throughout our working experience, some industries may need a larger size of sponge rollers. The larger size sponge could be 1.5m in length. […]

- On May, 14, 2021

- admin

We come across a user who asked us about the difference between the PVA brush and sponge. From our experience, in most cases, we are using the term PVA sponge while we discuss our product with users. However, in certain industries, they prefer the term PVA brush instead of PVA sponge. Base on our observation, […]

Plate Wash Roller in Printing Industry

- On Apr, 23, 2021

- admin

In the printing industry, the printing plate has to wash and dry with the PVA sponge roller to ensure the plate’s cleanliness. The aged printing plate will have some ink stain mark build-up after a certain cycle of printing. The contaminated plate shall send for plate cleaning. There are many types of roller in a […]

Continue Reading...- On Mar, 26, 2021

- admin

10 years ago, we are using a non-woven wiper in a cleanroom, but the situation changed recently. From our observation, we are seeing the many cleanrooms slowly convert to PVA foam wipers instead of non-woven wipers. In our last article, we have listed the reason why PVA foam wiper is more common in the cleanroom. […]

Continue Reading...- On Mar, 02, 2021

- admin

PVA foam wiper has an excellent water absorption capability. Our wiper foam design original uses in the cleaning process, however, some have expanded the application to household application. The two sport sectors, the swimming pool and gym, are always come with water and sweating. The PVA foam wiper becomes a good alternative to replace cotton […]

- On Feb, 25, 2021

- admin

We straight to the point, the dry PVA sponge roller will turn rigid and hard. This is the nature of PVA sponge characteristic which we have face every day. The PVA sponge roller remains at a wet stage right after our manufacturing process. Perhaps, the PVA sponge roller shall use in the wet stage during […]